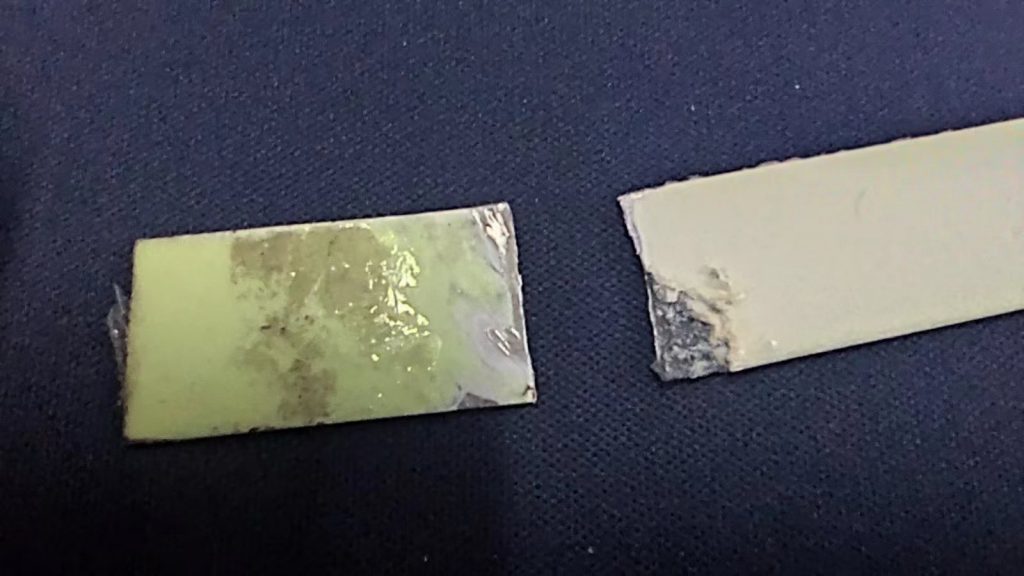

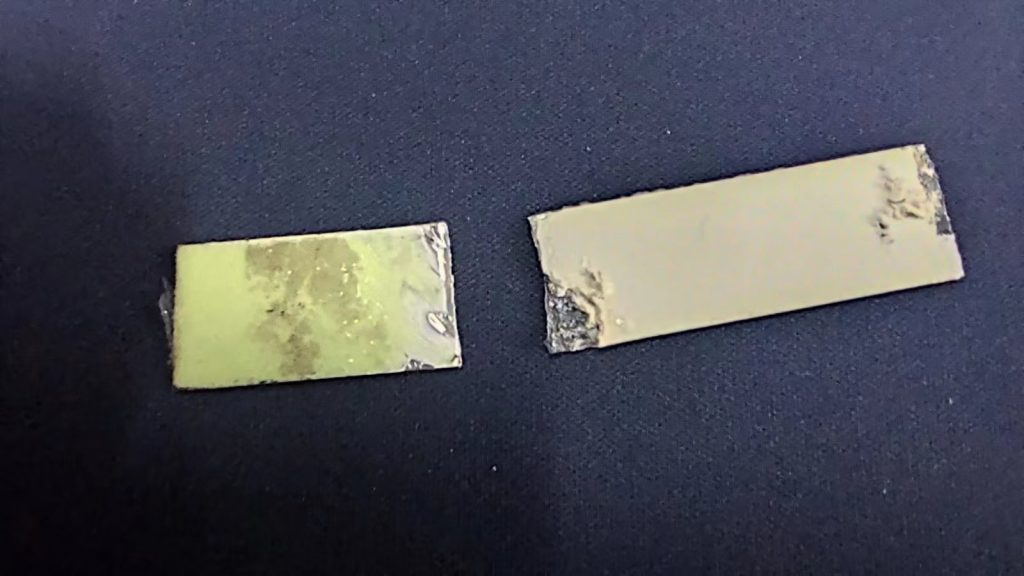

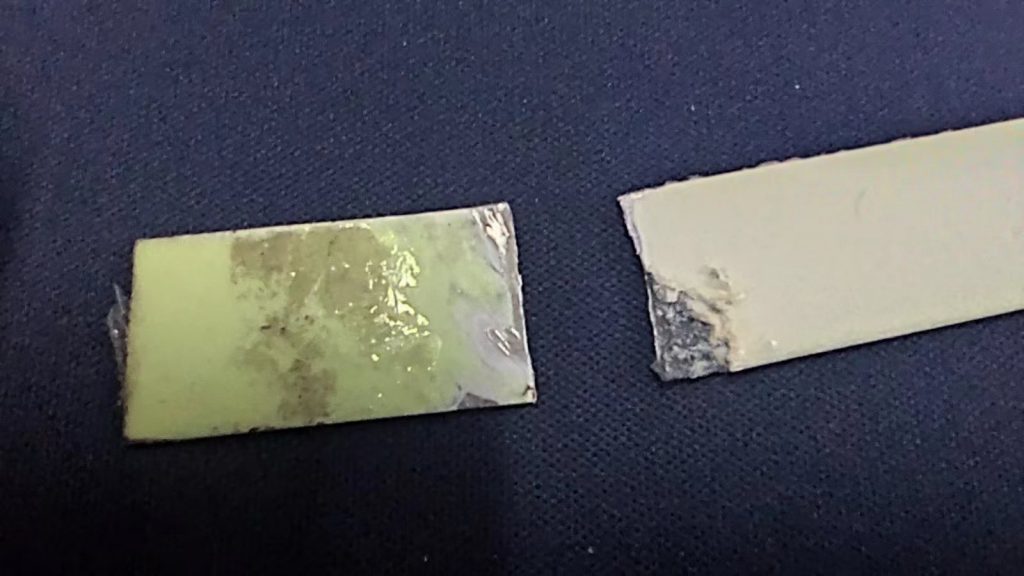

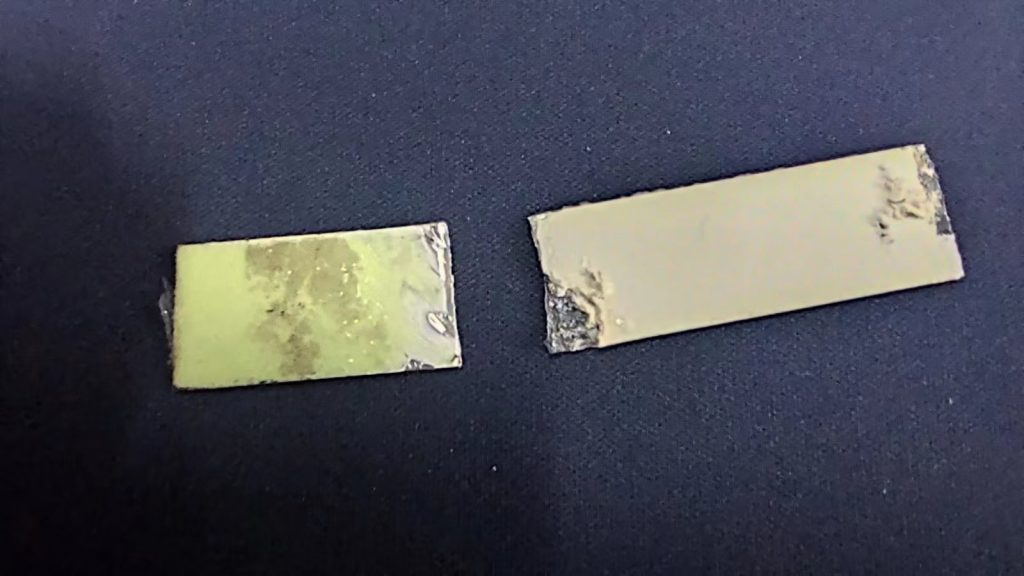

可以看出还是有比较明显的消退作用,需做好密封,外壳有裂纹时注意及时更换,以减少损伤。

可以看出还是有比较明显的消退作用,需做好密封,外壳有裂纹时注意及时更换,以减少损伤。

| 标题 | 737APU供油管外罩在翼修理 737 APU Fuel Feed Line Shroud On-Wing Repair |

|---|---|

| 编号 | 737NG-FTD-28-22001 737MAX-FTD-28-22003 |

| 章节 | 28 |

| 适用性 | 737NG/737MAX |

| 日期 | 2022年10月 |

| 机队影响 | ALL |

| 是否关闭 | 否 |

| 背景 | 737运营人经常报告APU供油管外罩的损伤。 此损伤之前只能通过更换外罩或者 依据CMM28-00-10进行离位修理来处理。 这两个方法都需要拆下损坏的供油管外罩, 需要消耗不少时间。 波音评估了在翼修理方法以减少处理此问题的时间 |

| 改进状态 | 波音正在评估关于APU供油管外罩的在翼修理方案, 作为CMM28-00-10修理的备选。 此修理需要制作并安装一个铝加强板来包裹住防护罩损伤的部分。 这个修理方案处于工程开发的阶段,一旦得到许可, 便可以显著减少处理此类损伤的时间。 波音公司目前正在制定一项测试计划, 以收集所有必要的数据,以证实此维修可行。 |

| 临时措施 | 如果发现APU供油管外罩损伤, 请依据AMM 28-22-15-700-801处理损伤 |

| 最终方案 | 如果在翼修理方案得到了批准, 运营人可以考虑在遇到APU供油管外罩损伤时执行在翼修理 |

| 点评 | N/A |

外部航司案例

有飞机左组件频繁反应再现组件灯亮的问题,故障代码指向左侧混合总管温度传感器,经对串传感器、ZTC、PFTC和线路检查未见异常,故障依旧反复发生。经与波音沟通,反应该现象在BCF飞机上偶有发生,认为是由于TCV的热气与ACM冷气混合不均,导致传感器感受到了200F的温度超过6.2秒,从而记录信息,可以通过加电阻的方式缓解。

Boeing have already revived couple of similar reports from other 737-800BCF operators. The root cause for this chronic left mix manifold sensor fault was determined to be poor mixing of the hot (TCV open) and cold air at the left mix manifold sensor. This resulted in the sensor detecting about 200 degrees Fahrenheit air temperature in a heating mode for more than 6.2 seconds, thus triggering the Mix Manifold Temperature Sensor Short Fault. The solution is to add a 200 ohm inline resistor to the mix manifold sensor. The resistor(s) are to be installed near E3-3 D41800P (reference

Wiring Diagram Manual (WDM) section 21-51-12) for both left and right (optional) mix manifold sensors. For detailed work instructions, PNs and RDR (Repair and Deviation Record), please have your avionics engineer submit a Service Request.

波音考虑到这是假信息,只要可以复位,允许持续运行。

SR 4-5653423749

实际案例中遇到,有飞机启发后出现EEC备用灯亮故障,自检右发EEC有73-31642 ADIRU 1 and ADIRU 2 Total Pressure Data Disagree 信息,针对是否仅需要根据EEC备用灯亮直接MEL放行飞机,还是介于总压信号需核实皮托管,以免产生更严重的空速不一致等异常,存在一定的争议。与波音做了沟通,波音认为在使用MEL之前,运营人实际已经做了故障隔离确认工作,方可使用MEL进行保留放行。

这与此前大家的理解还是存在一定差异的。

Prior to dispatching airplane with appropriate MMEL item’s, MAINTENANCE (M) and OPERATIONS (O) procedures provided in the DDG it is assumed that the operator has already confirmed the failure or abnormal system behavior. The airplane may then be dispatched by using Boeing suggested DDG (M) and/or (O) procedures or operator defined (M) and/or (O) procedures. Operators can use Boeing suggested (M) and/or (O) procedures along with additional information which may help in their company MEL, subject to the approval of their local regulatory agency.

It is important to note that the DDG procedures are not intended for troubleshooting. It is the responsibility of the operator to first troubleshoot the nature of the failure before entering the MEL in order to determine whether appropriate MEL dispatch relief can be applied.

In the case of MEL 73-11-11, there are no (M) procedures associated with the MEL item. The MMEL assumes that adequate troubleshooting has been performed prior to applying MMEL dispatch relief. The DDG is not intended to be a troubleshooting document. Troubleshooting must be performed using the FIM/AMM to isolate the failure, so that the appropriate MMEL dispatch relief may be applied. HNA should troubleshoot any relevant engine and/or indication related messages via AMM/FIM before applying MEL 73-11-11.

Boeing will not revise MEL 73-11-01 to accommodate any relevant engine and/or indication related messages since the DDG assumes that is already done as described above.