1、SR HNA-HNA-24-0385-02B

为什么只有落地超轮速的特检AMM 05-51-07-000-801,没有起飞超轮速的特检。具体该如何操作。

因为波音没有执行过起飞超轮速的试验。

Boeing has reviewed Hainan Airlines’ inquiry and offers the following response:

Boeing is aware that overspeed takeoffs occasionally occur in the fleet and it is rare to see a tire fail simply due to a mild overspeed takeoff event. The potential tire problems resulting from a mild overspeed takeoff condition are problems which can also arise without an overspeed event, as they are most likely due to an existing fault (such as an internal separation or a deep cut that could result in a peeled rib or an entire tread loss). Boeing is unaware of any wheel failures that have occurred due to a mild overspeed takeoff event.

Since there have been no tire overspeed takeoff design requirements imposed or qualification tests performed, Boeing cannot formally approve allowing a wheel/tire assembly with overspeed takeoffs to remain in service. However, because of the fleet service history noted above Boeing has no technical objection if, in lieu of removal, operators examine wheels/tires following a very mild overspeed takeoff event using the existing criteria in AMM 32-45-00 TASK 32-45-00-700-803 and if no damage is found return the airplane to service. In addition, Boeing recommends that the tire serial numbers be recorded and that the tire retreader be informed of the overspeed event history when the tires are returned for retread. If Hainan Airlines decides to do this inspection/return to service in lieu of replacement please note that Hainan Airlines has the responsibility to coordinate with the appropriate regulatory agency (or agencies) to obtain all necessary approvals. If Hainan Airlines elects instead to remove the tires, the normal tire change inspection interval criteria (per applicable CMM) for the wheels is recommended.

Boeing has published an article in its AERO magazine that covers this topic (see Ref /A/ file attached). We suggest that Hainan Airlines review this article and in particular the section on Maintenance Actions near the end of the article.

2、SR HNA-HNA-21-1111

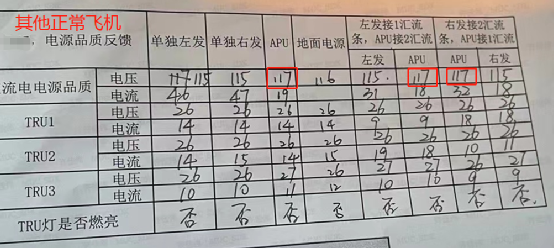

当出现起落架超轮速后,会有什么结果,能否放行。(225轮胎,安监的监控值为185节)

波音认为从部分航司的实际操作看,2-3节并没有发生问题。波音不反对这种情况。对于225的胎,建议设置监控为195.5。

Boeing is aware that, in China, due to advances in flight data recorder technology that enables easier data acquisition, widespread recognition of tire-speed-limit exceedance events during takeoff has been materialized. However, we have to caution our airline customers against rash decisions such as setting a warning threshold value as the safety check line.

There are no standardized industry maintenance guidelines if a tire speed exceedance occurs during takeoff. If the overspeed was very small (2 to 3 knots over the tires’ speed limit), it is unlikely that the tires would have suffered any damage. Some operators have elected to simply examine the tires after an overspeed takeoff event using the normal tire inspection criteria in the Airplane Maintenance Manual. If no damage is found, the airplanes are dispatched normally and no further maintenance actions are performed. Based on many years of service experience, this approach seems to have worked well, and Boeing has typically not objected to this practice because very few, if any, tire tread losses have been attributed to an overspeed event.

Note that tire speed ratings and tire overspeed capabilities are provided in the approved Boeing AFMs for 737 MAX, 777, 787 and 747-400/-8. For example, the following statements are included in all AFMs published for the 737 MAX:

Approved tires with a speed rating of at least 235 mph and a one-time overspeed capability of 260 mph must be installed on the airplane to utilize the allowable tire speed limit of 232 mph in AFM-DPI.

An option exists in AFM-DPI to utilize a reduced tire speed limit of 225 mph for approved tires with a speed rating of at least 225 mph and a one-time overspeed capability of 250 mph.

When an aircraft is dispatched in accordance with certification and operational regulations, the calculated takeoff performance guarantees that the airplane’s ground speed at the liftoff during takeoff ground roll will not exceed the tire speed rating (e.g. 225 mph or 195.5 knots for 737NG), provided Boeing-recommended all-engine normal takeoff rotation procedure in the Flight Crew Training Manual (FCTM) is followed. Therefore, a threshold value for tire overspeed event alert should be set and selected according to approved AFMs. In the AFM-DPI for 737NG, the value for tire speed rating is listed as 225 mph on the CONFIGURATION page, and Boeing recommends 225 mph or 195.5 knots as the limited ground speed for tire overspeed alert.

3、SR HNA-HNA-18-0855-02B

轮胎225的含义、超轮速了该怎么办、超轮速后是否应该更换刹车或轮胎。

对应地速195节,执行特检,有公司检查后放行。

Question 1:

What is the meaning of 225MPH on the tires’ sidewall? The airplane ground speed or the wheel speed?

Answer 1:

The tire speed and wheel speed is the same as they both move together as a single unit. It is important to remember that at high speeds, heat is generated within the tire structure. This heat, combined with extreme centrifugal forces from high rotational speeds, creates the potential for tread loss. Ensuring that tires are operated within their speed ratings will help prevent possible tread losses and the potential for airplane damage.

While rotation and liftoff/landing speeds are generally expressed in knots indicated airspeed, the tire speed limit is the ground speed, which is usually expressed in statute miles per hour. This means that a tire rated at 225 miles per hour is designed for a maximum ground speed at liftoff/landing of 195 knots.

Question 2:

When the speed of our airplane is out of 225MPH, how do maintenance recognize the overspeed information?

Answer 2:

When an overspeed landing is suspected, Boeing recommends performing AMM sub-task 05-51-07-210-801 when tires have been subjected to an overspeed landing above the rated tire speed. If the Step 2.A(4) brake energy calculation of that AMM shows that the landing was not in the CAUTION or FUSE PLUG MELT range and no fuse plugs actually melted, then only TASK 05-51-07-000-801 (Tire Removal After Overspeed Landing) needs to be accomplished.

If the Step 2.A(4) brake energy calculation shows that the landing was in either the CAUTION or FUSE PLUG MELT range or if any fuse plugs actually melted, then the appropriate additional AMM 05-51-07 inspections (High Energy Stop Conditional Inspection – In CAUTION range or the High Energy Stop Conditional Inspection – In FUSE PLUG MELT range) also need to be accomplished in addition to the tire removal.

Question 3:

If an overspeed event occurred, is it necessary that we should change the wheel or the tire?

Answer 3:

Some operators have elected to simply examine the tires after an overspeed takeoff/landing event using the normal tire inspection criteria in Chapter 32 of the AMM. If no damage is found, the airplanes are dispatched normally and no further maintenance actions are performed. Based on many years of service experience, this approach seems to have worked well because very few, if any, tire tread losses have been attributed to an overspeed event. Based on this service experience, Boeing has typically not objected to this practice.

4、SR HNA-HNA-24-0877-02B

向波音申请在195-198期间的超速情况,当段完成正常轮胎检查,航后更换。波音技术不反对。

Question 1:

What inspection is required to do for the takeoff tire overspeed and landing tire overspeed respectively?

Answer 1:

Boeing is aware that overspeed takeoffs and landings occasionally occur in the fleet and it is rare to see a tire fail simply due to a mild overspeed takeoff event, such as 2 – 3 miles per hour. Therefore, since there have been no tire overspeed takeoff / landings design requirements imposed or qualification tests performed, Boeing cannot formally approve allowing a wheel/tire assembly with overspeed takeoffs to remain in service. Hence, if a tire speed rating is exceeded (during takeoff or landing), Boeing recommends removing the tire from service. However, because of the fleet service history noted above, Boeing has No Technical Objection (NTO) for Operators to examine wheels/tires following a mild overspeed takeoff event (2 – 3 mph), using the existing criteria in Boeing’s 737NG AMM Task 32-45-00-700-803 ‘Tires – Inspection’. If no damage is found, Boeing is aware Operators have returned the tire into continued service. If this mild overspeed condition occurs, Boeing recommends that the tire serial numbers be recorded and that the tire retreader be informed of the overspeed event history when the tires are returned for retread. If a large overspeed condition has occured (above the 2 – 3 mph range), Boeing recommends the tire be removed from service as soon as the overspeed condition has been confirmed. Operating the tire in this condition can cause the tire to fail as explained in ‘Answer 2’ below.

Question 2:

What is the main influence, which the tire overspeed pose to the tire? Are there any inspections which can discover the overspeed status for tires?

Answer 2:

As noted in HNA-HNA-18-0855-02B, it is important to remember that at high speeds, heat is generated within the tire structure. This heat, combined with extreme centrifugal forces from high rotational speeds, creates the potential for tread loss. Ensuring that tires are operated within their speed ratings will help prevent possible tread losses and the potential for airplane damage. Unfortunately the only way to properly inspect the tire for damage is when the tire retreader performs its NDT inspections. This can only be done in a shop once the tire has been removed from the wheel.

Question 3:

HNA guess there is no risk when the groundspeed is less than 198 knots for the 225mph type tire according to the the article in the AERO magazine and the SR mentioned above. HNA is going to make a policy, when the groundspeed is between 195 and 198,the tires are arranged to be replaced in the first AF phase. Could BEOEING offer an NTO ?

Answer 3:

Boeing has No Technical Objection (NTO) if Hainan Airlines Holding creates a policy when an airplane exceeds 195 knots (224.4 mph) and performs the recommendations outlined in ‘Answer 1’ and ‘Answer 2’ above.