ISE-52-23-43195

ASA开贴

在过去两年中,ASA一直收到越来越多关于登机门和勤务门意外解锁的报告,其中一些导致了重大事件,例如中断起飞(ATOs)或空中返航(ATBs)。这些意外松开发生在飞行的不同阶段。很多时候,维修人员检查并操作门后未发现任何故障,结果是在未进行任何调整的情况下将门重新投入使用。目前,ASA在我们的登机门和勤务门上执行以下计划:

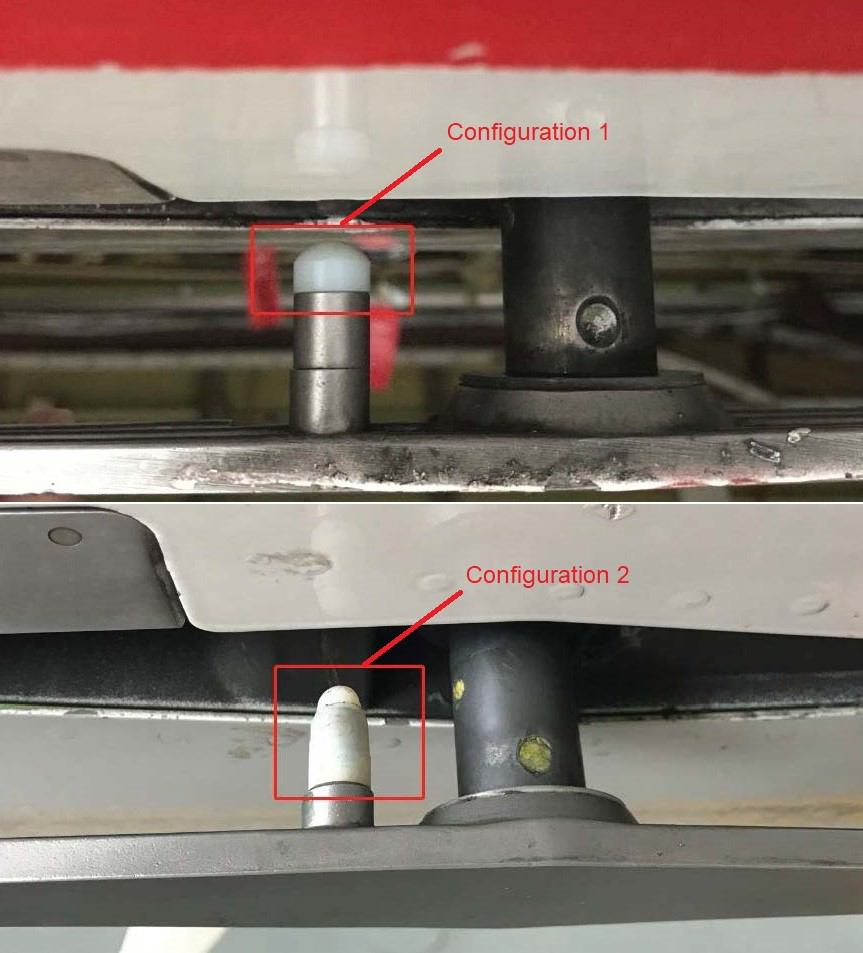

1、每两年进行一次门“健康检查”,包括门系统测试、导向臂检查/调整、扭矩管检查、导向板检查、锁扣接收器调整和止动销调整。在检查结束时,再次进行门系统测试,包括检查并记录手柄开启/关闭扭矩值。

2、每六年进行一次门“翻新”,包括拆除门、更换磨损部件以及重新安装并测试门。

提出两个问题:

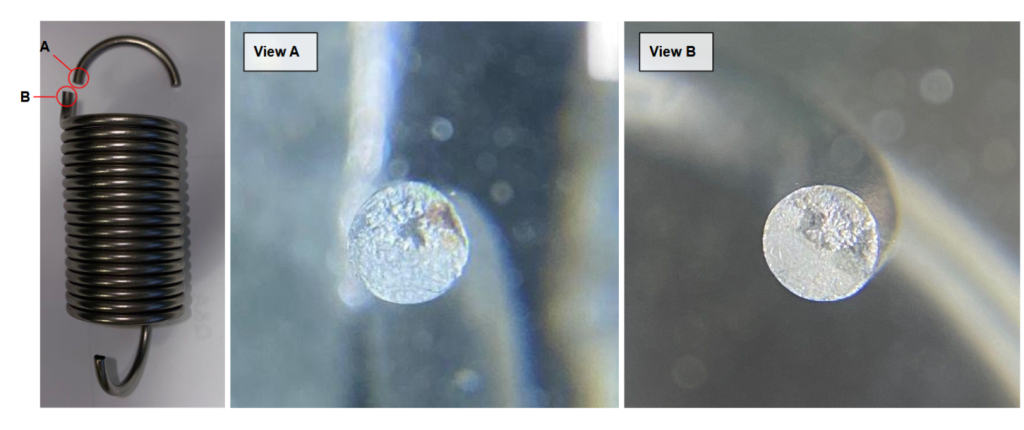

波音公司之前发布了737NG-FTD-52-16002号机队团队摘要,建议运营商更换L1门传感器组件,使用零件号为284A1322-9的传感器,该传感器的弹簧力较小,可降低在增压过程中活塞将锁扣扭矩管推回开启位置的可能性。是否有运营商按照FTD的建议更换了门传感器,并发现L1门意外松开问题有所减少?

是否有运营商对有效的意外松开问题处理计划或对飞行中出现且无法在地面重现的意外松开问题的故障排除方法有反馈?

AA跟帖表示机队中发生了很多此类事件。

Copa航空跟帖

Copa航空也遭遇了多起与登机门和服务门意外松开事件相关的AOG(飞机地面停飞)情况,驾驶舱指示灯也会亮起。在地面进行增压测试、滑行和拖曳时,也能复现门意外松开的情况,最终不得不更换整个门的调节装置和/或门警告传感器组件。

在Copa航空,门会在大修期间进行翻新,并且在A检时经常进行调整,以避免像ASA在IdeaXchange中提到的类似运营中的事件。在大多数情况下,调整包括导向臂、止动销、蒙皮平整度以及传感器指示器的更换,这导致了大量维修工作。然而,在按计划进行门调整后,经过相对较短的时间,意外松开事件仍然会发生。

VOZ跟帖

VOZ近期也遭遇了类似的问题,并且最近在对一架问题飞机进行故障排查时,通过在飞机增压(压差1psi)状态下检查舱门手柄的开启扭矩,并据此相应地调整舱门锁扣板(door latching plates),涉及的那架飞机上最初门的开启力矩仅为80英寸磅,经过调整后,平均开启力矩达到160英寸磅(在增压过程中)。自调整以来,该飞机再也没有出现过“软解锁”或“门难以开启/关闭”的报告。成功地解决了该飞机的舱门意外松开缺陷,从而实现了令人满意的锁扣扭矩。这一措施有效修复了该飞机的舱门意外松开问题。

VOZ随后提交了BCS VOZ-VOZ-23-0294-04B,详细记录了锁扣板调整后所获得的所有舱门调节测量数据,并请求更新737NG-FTD-52-16002和/或AMM 52-11-00-820-801,以纳入替代的故障排查方法。

由于零部件供应问题,VOZ尚未能够将L1舱门传感器(S199)更换为弹簧力更小的件号(284A1322-9)。

VOZ也认同波音公司应在下一期机队团队摘要(FTM)中纳入这一常见问题。

YTH跟帖

YTH在滑行期间因登机门手柄轻微弹起而出现了登机门警告灯亮的情况。AMM TASK 52-11-00-700-804中给出了打开内侧门把手的最大扭矩值为420英寸-磅,但AMM中并未给出打开内侧门把手的最小扭矩值。YTH想知道VOZ在1.0PSI增压状态下打开内侧门把手的最小扭矩值方面是否有相关经验。

UAL跟帖

UAL最近也遭遇了类似的问题,运营中断的情况明显增加。目前,UAL每六年进行一次离翼登机门大修,包括检查、零部件更换以及重新安装时的全面门调节。鉴于这一问题早在几年前就首次被提出,UAL希望了解为缓解意外松开问题而采取的任何额外措施。在ASA最初提出的问题基础上,进一步增加了一些询问:

1、是否有运营商按照737NG-FTD-52-16002的建议更换了门传感器?如果有,他们是否观察到L1门意外松开问题有所减少?

2、AMM 52-11-00-820-802概述了检查L1门意外松开的程序。其他运营商是否发现这一程序作为两次大修之间的预防措施是有效的?

3、机场运营或乘务员程序的变更——例如确保乘务员在起飞前完全按下把手——是否有助于减少这些事件的发生频率?

案例补充:

外部航司

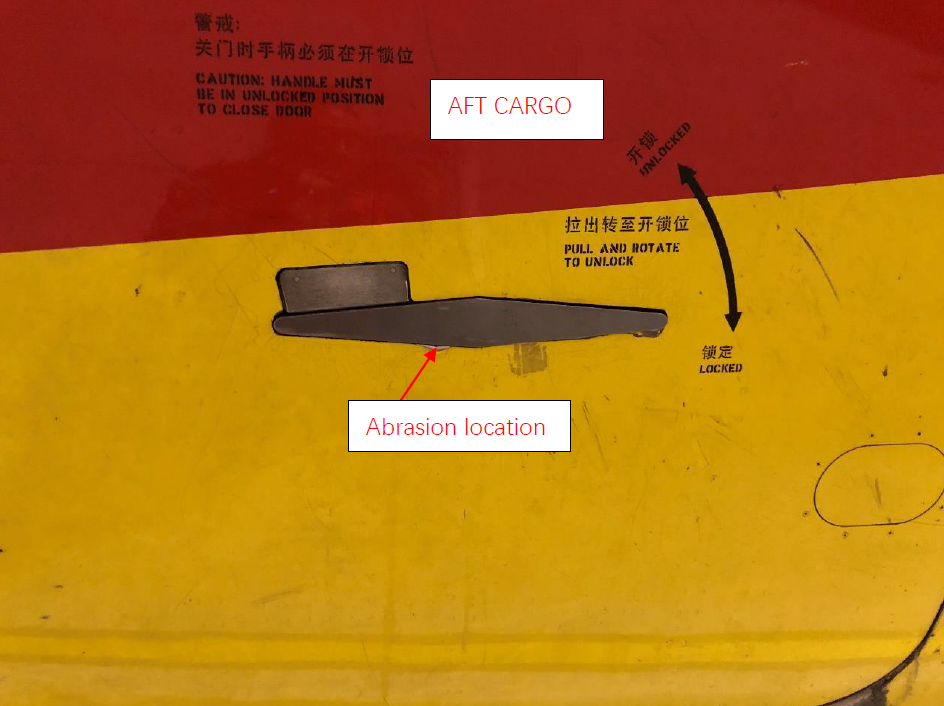

有航司出港起飞滑跑时左前登机门门警灯闪亮,机组中断起飞,中断速度约40节。飞机滑回之后办理左前登机门门警告系统保留后放行,航班延误134分钟。

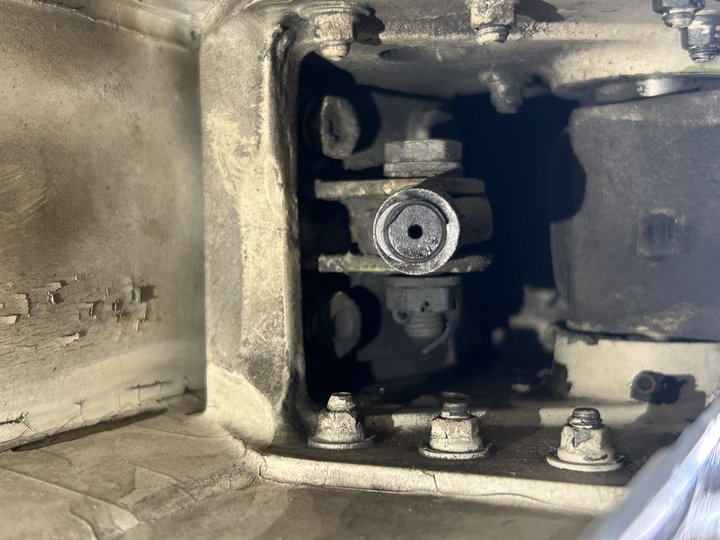

1.飞机滑回后完成PSEU自检,当前正常无代码,查看前登机门传感器S199间隙正常,门机构操作测试正常。PSEU读取S199间隙102MILS(标准100 MILS+/-20 MILS)在范围内。左前登机门机构操作测试正常。

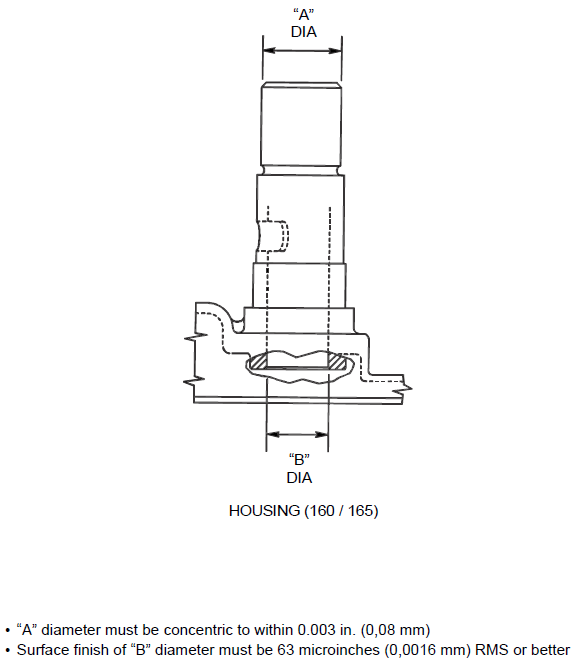

2.航后排故检查S199电门间隙,100MILS。飞机不增压情况下手柄解锁力23磅,增压1Psi情况下解锁力10磅,不满足建议15磅要求。检查并调节左前登记门止动钉,调节止动钉后重新测量手柄解锁力,不增压情况下手柄解锁力26磅,增压1PSI情况下解锁力17磅。

3.更换S199电门,测试正常。前登机门关闭PSEU指示100mils。完成PSEU操作测试,检查正常。

4.该机排故部件、区域和飞机系统,近1个月未执行过相关维修工作。该相同故障现象在本机近一年内没有发生过。

点评:可以将增压1Psi情况下解锁力15磅加入排故SOP和检查要求。