一、豁口导致的EDP无输出压力

自有案例 SR HNA-HNA-23-2257-03C

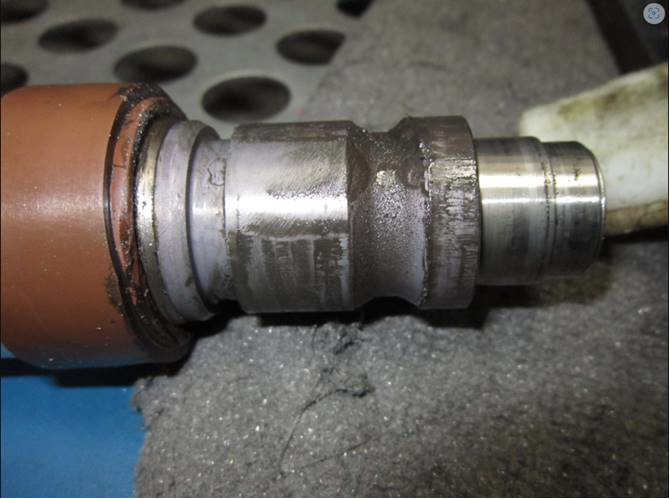

2023年4月,有飞机反应EDP低压灯亮,试车无输出压力。检查中发现吊架管路转接头豁口,导致管路松脱,液压油在自封活门的作用下,无法进入。该失效模式为机队罕见,接近工作检查中需注意。

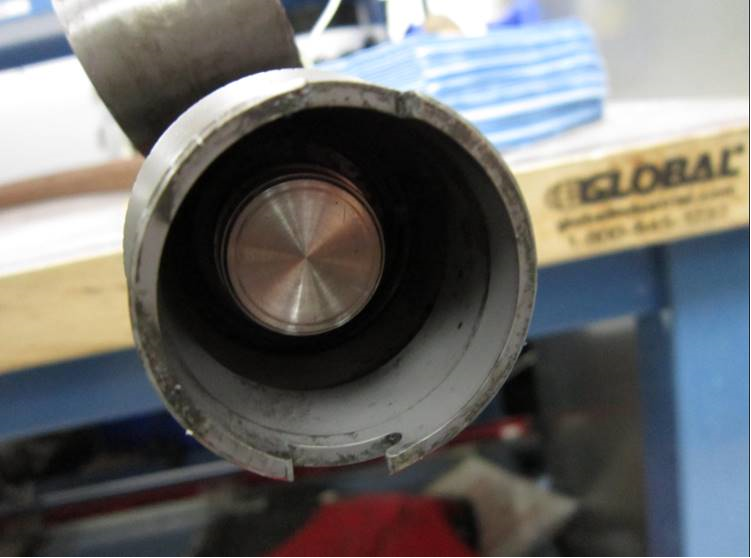

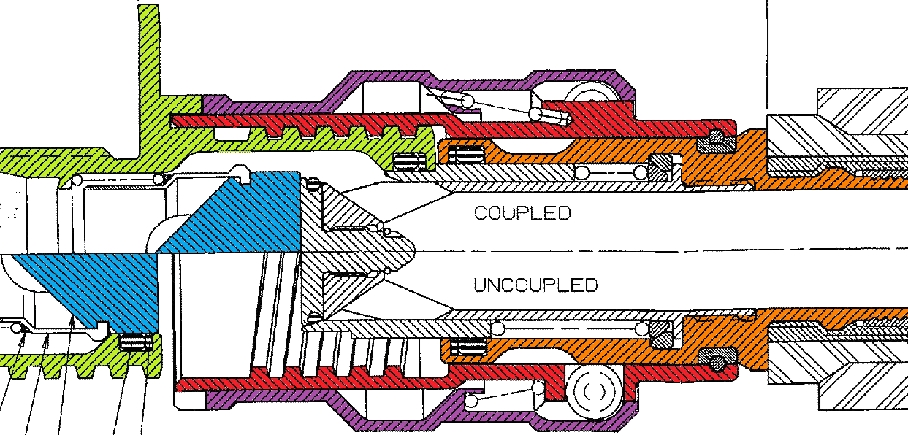

组装方式

正常卡口

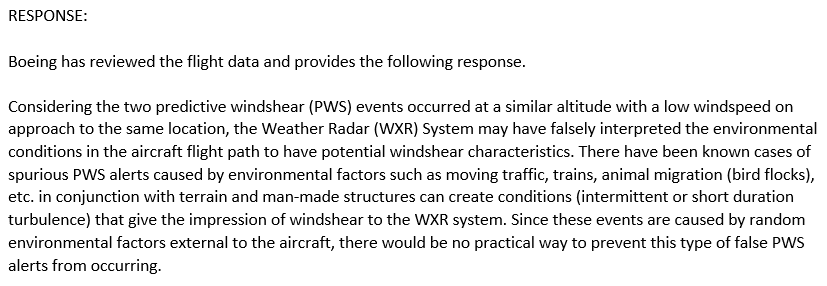

入场分解照片如下,也发现了较为明确的磨损痕迹。

2023年10月补充案例

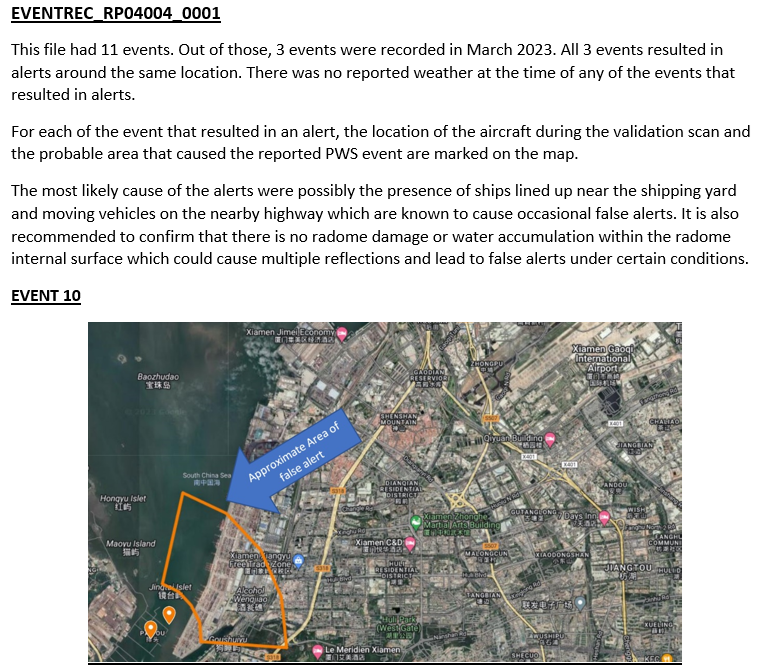

B-14*2飞机反映巡航阶段B系统低压灯亮,慢车验证右发B系统EDP无压力输出,进一步检查右发EDP供压管脱开(吊架处),检查发现管接头损坏。

和波音SR HNA-HNA-23-2257-03C 进行了沟通,波音反馈很少收到此类报告。针对该损伤,主要有两方面原因:一是由于液压接头接口部件之间的相对运动。另一方面是液压接头上的配合锁片啮合不当导致。并建议通过定期措施对供压管路和快卸接头进行检查确保状态正常。

将该液压管调回做了分解,可以看出管路的损伤主要分为三个部分:

1,供压管的管套断裂,有可见磨损痕迹。

2,管路外壁被磨出了缺口。

3,两个卡扣均被拉断

从原理来说,管口部分由以下三个部分组成,其中内外管套组装好后,压缩弹簧,在内外管套上均有小孔作为弹簧的安装点。其中外管套有一个孔,内管套有三个孔方便调节位置。

从对比看,断裂点和外部的缺口点是吻合的,和内管套位置对比位于弹簧压缩的尖端。

因而推导整个失效过程为,管路初始装配的时候,弹簧安装在外管套这边的头未能有效固定,在使用后这个头出现了脱出,弹簧发生了移位,卡在内外管套壁之间,通过转动外套也发现,无法转动。而正常适配的是可以自由转动,来与接头螺纹连接的。由于管路连接处始终受到管路压力变化的作用,内外管套也发生微小的位移,与弹簧出现反复磨损,内管套就出现损伤后在拉紧力下出现裂纹,裂纹慢慢扩展,最终被环切。外管套摩擦出缺口。内管套被环切后就失去螺纹咬合的力。仅靠两个锁扣相连,当锁扣被反复的加减压应力断裂后,管路就脱开,表现出无法供压。

损伤管分解图

当前有EO737-29-0074,以300FH为间隔重复执行管路接头检查。

当前管控措施

当前通过以下工程措施来确保管路安装到位,并进行定期检查和识别。

1. MT23-737-29-035 关于737飞机EDP管路安装的维护提示。确保管路安装到位。

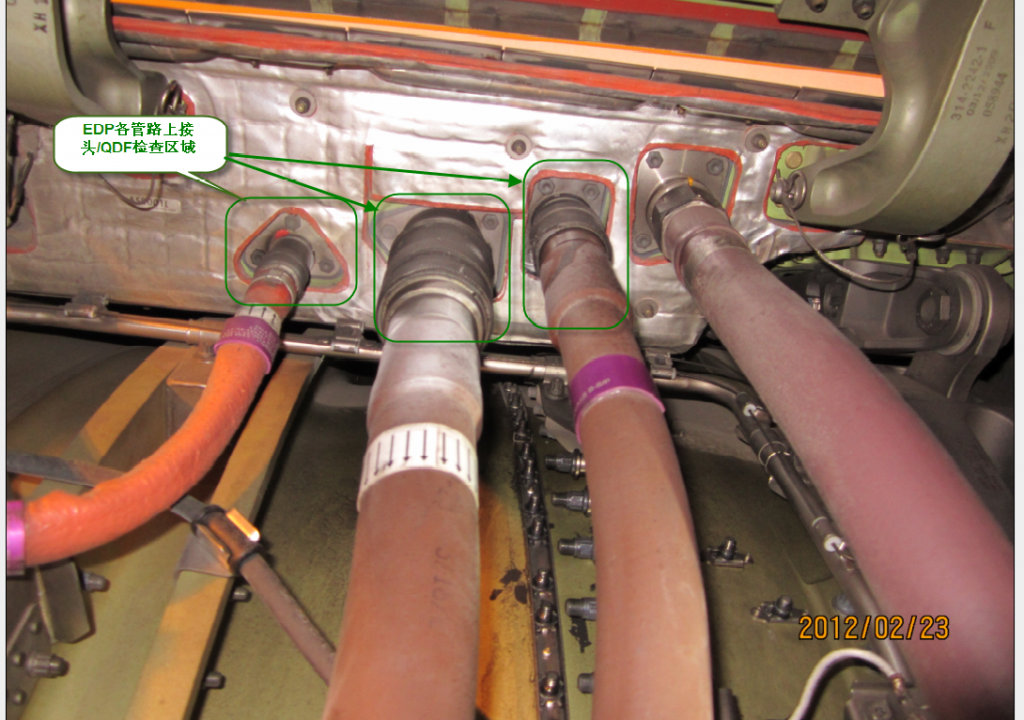

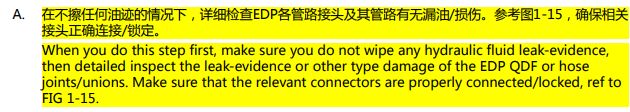

2. EO-73N-29-2020-010 每1200FH检查和清洁B737机体液压部件。其中针对EDP需检查相关各管路接头无漏油,且接头正确连接/锁定,同时加入例图进行了说明。

措施评估

由于该损伤是在同一架飞机上发生,管路未做过修理,因此分析是出厂装配质量问题。同时,该损伤后,由于自封功能,并不会发生大量渗漏等严重后果的事件。结合厂家建议,目前已有相关维护提示和定期措施进行覆盖,评估暂不增加其他管控措施。

工卡截图:

二、底座漏油