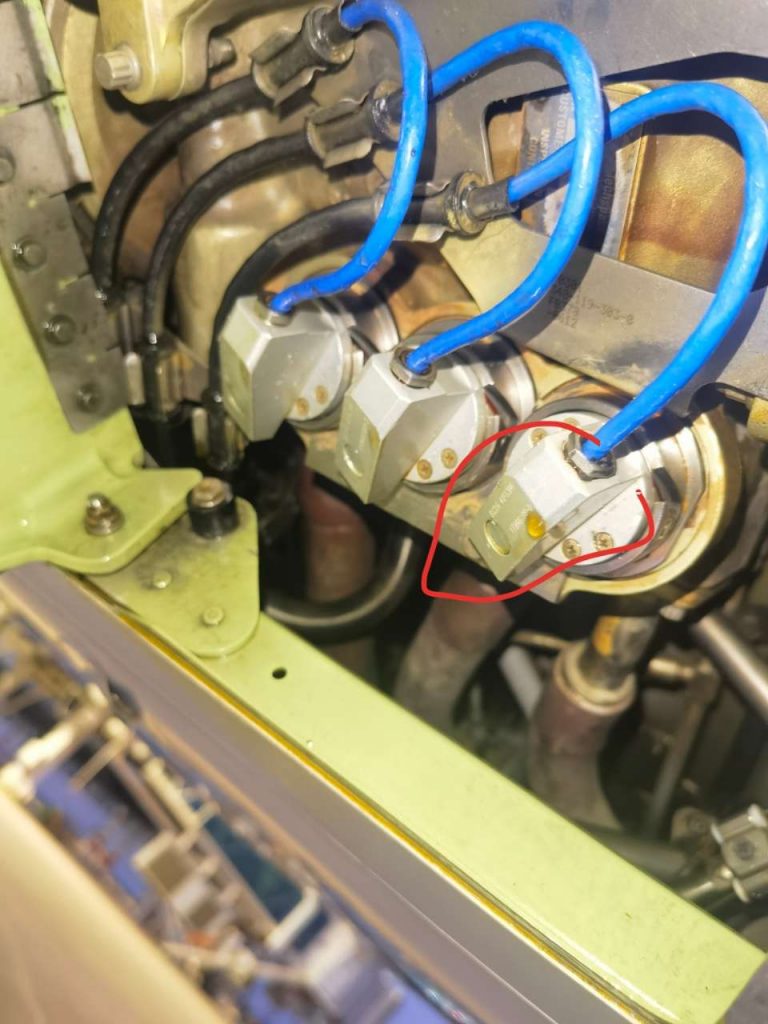

2023年11月,有飞机反映电磁堵本体渗油,更换封圈无效,更换电磁堵后不漏。

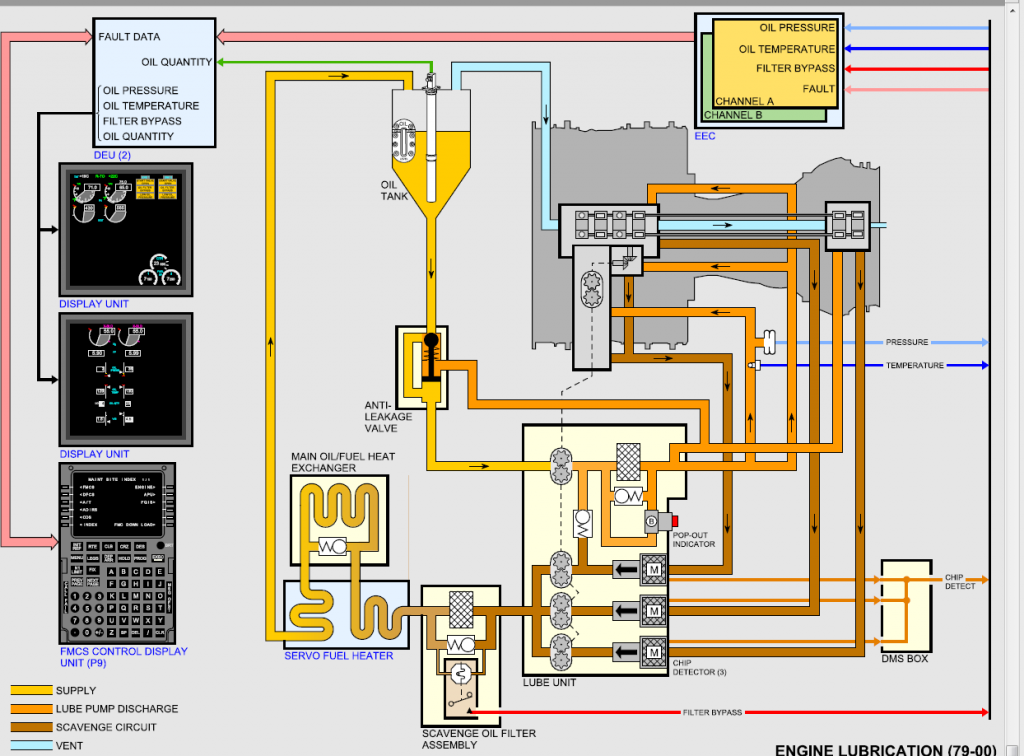

从系统看磁堵位于回油路上,油压并不高。

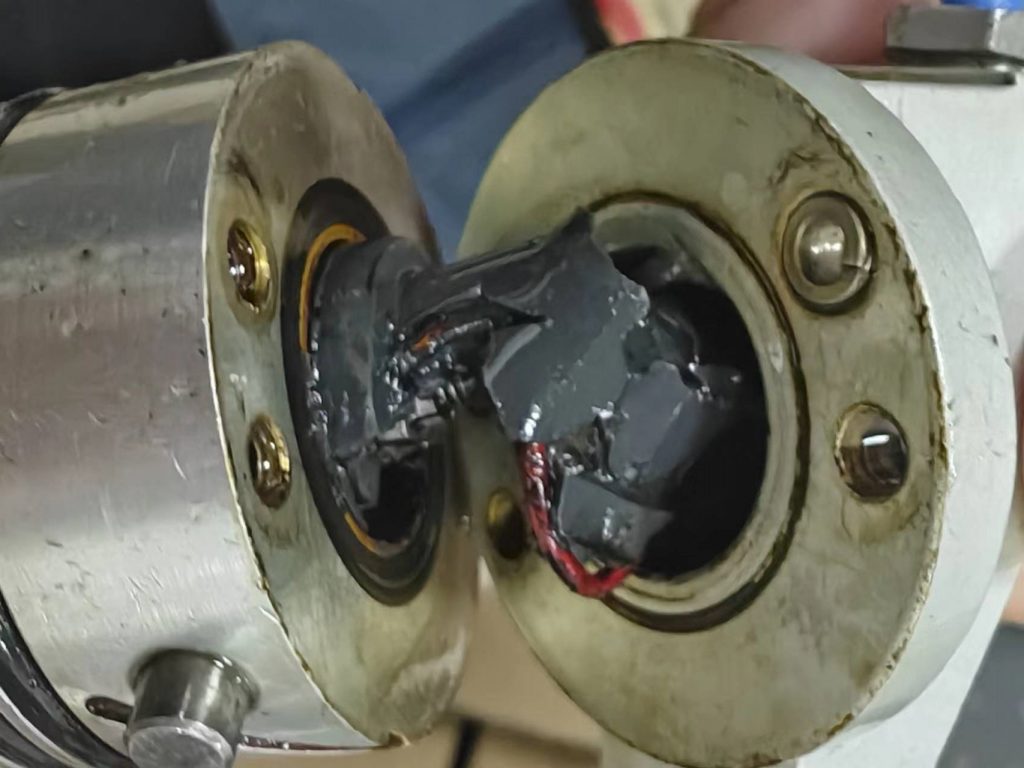

对磁堵做了分解,可以看出电感部分一直深入到探头端部,中间填胶处理。拆解后发现胶体部分已经被滑油浸泡。

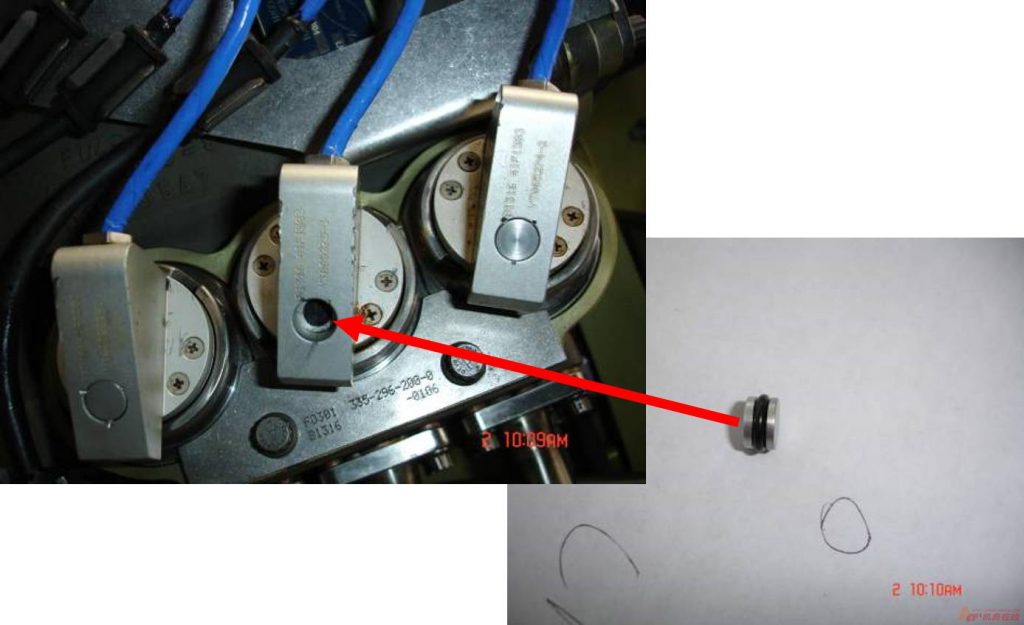

有外部航司反映过堵头丢失的情况,该堵头带封圈。且丢失后不会漏油。从实物检查看,堵头是被基座金属冲出的三个凹槽挡住的(金属形变),一般情况不会导致渗漏。

波音表示:

1,此堵头是用来密封填充了绝缘化合物的磁堵头部空腔的。

2,如果堵头长时间丢失并且(或)磁堵头部接触到影响其可靠性的液体,可能会对磁堵造成某些长期影响。

3,此堵头丢失没有运行上的限制。但是,可能会对系统造成长期的负面影响,所以应该在尽可能早的维修机会修复。

基于此,分析其制造工艺应该是杆体部分和磁感部分先用4颗螺钉安装紧固,再通过小孔注胶,最后封堵小孔,如果填胶有空隙,是有可能导致滑油的滴落,但这种不会造成崩溃性的渗漏。

GE表示:

CFM SSE已审阅关于DMS检测器插头周围发现油迹的案例。实际上,圈中的“头插”(在图片中)是一个带有密封圈的小圆件。这个插头的目的是密封充满绝缘材料的头部内部腔室。由于头部腔室与润滑单元油路不接触,从CFM的经验来看,此前的案例表明,在短期内,缺少DMS头插对飞机和发动机的操作没有影响,CFM SSE也不了解有关油从头插内部泄漏的报告。 对于DMS检测器上的油迹,CFM SSE建议按照AMM任务79-00-00-200-804-F00执行磨屑探测器和污油过滤器检查,寻找任何在过滤器中的碎片,并检查DMS检测器是否正确安装。

2025年12月案例补充

GE答复

关于您的请求,请参阅以下最终答案:

客户问题 1:请 CFM 确认是否有任何装运条件会导致插头弹出或缺失情况,以及在这种情况下我们应该怎么做。

CFM 回答:DMS 头部插头对飞机和发动机的操作没有直接影响,但它密封了内部腔室与环境。

这个主题在 CFM 一侧是已知的话题。根据 AMM 任务 79-21-05-400-805-F00 – 循环监测系统 (DMS) 检测器安装 注意事项:确保 DMS 圆头插头(插头柄上的小圆平片)存在。如果有孔,应尽快更换 DMS。

缺失的 DMS 头部插头在短期内不会影响发动机操作。头部腔室不与润滑单元油路接触。

然而,没有这个圆头插头,油和/或碎片可能会进入腔室,它有密封圈,将内部腔室与环境隔开。对于此发现没有维修方法,必须完全更换 DMS 检测器。根据 AMM 任务 79-21-05-400-805-F00,CFM 建议在最早的机会时更换 DMS 传感器。

没有针对机翼条件下可用的维修方法。必须将其移除并用可使用的更换。CFM 建议联系 CSC 以检查在 AOG 情况下是否有可能下订单。有关信息,有库存的件号:41F1304

如有需要,请在 AOG 基础上重新打开此案以满足物流请求。

客户问题 2:请 CFM 告知我们 AGB/前向和后向 DMS 检测器插头分别是否有泄漏限制。或者,如果润滑单元区域内的 3 个 DMS 检测器插头是否有油泄漏限制。以及如何确认油泄漏率。

CFM 回答 2:DMS 检测器插头没有泄漏限制,参见回答 1,头部腔室不与润滑单元油路接触。因此,在此区域内发现油时,CFM 的建议是检查 MCD 油箱是否正确安装,并检查密封圈状况,如有泄漏怀疑,请根据 TASK 79-00-00-200-802-F00 2. 外部油系统检查进行油系统检查。

With regards to your request, please see the following Final Answer:

Customer question 1 : Please CFM confirm is there any dispatch criterion to the plug pop out or missing condition and what should we do in this situation.

CFM answer : DMS head plug has no direct effect on aircraft and engine operation but It seals off the internal cavity from environment.

This subject is a known topic on CFM side. Following AMM TASK 79-21-05-400-805-F00 – Debris Monitoring System (DMS) Detector Installation NOTE: Make sure that there is the DMS round-head plug (small round and flat piece on the plug handle). If there is a hole, replace the DMS as quickly as possible.

Missing DMS head plug has no effect on engine operation for a short period of time. The head cavity is not in contact with the lube unit oil circuit.

However without this round head plug, Oil and/or debris could get inside the cavity, it has o-ring and will seal off the internal cavity from environment. There is no repair available regarding this finding, the DMS Detector as to be replaced in totality. Following , AMM TASK 79-21-05-400-805-F00 CFM recommends to replace the DMS sensor at first opportunity.

No repair is available for on wing condition. This must be removed and replaced by a serviceable one. CFM suggest to contact the CSC to check if there is any possibility to place an order on AOG situation . For information there is stock for PN/ : 41F1304

If needed ask to re-open this case on AOG Basis for Logistic request.

Customer question 2 : Please CFM advise us if there is leakage limit for AGB/ fwd and aft DMS detector plug respectively . Or if there is oil leakage limit total 3 ea DMS detector plugs in the lubricate units area. And how to confirm the oil leakage rate.

CFM answer 2 : There is no leakage limit for DMS detector plug , refering to Answer 1, The head cavity is not in contact with the lube unit oil circuit. consequently, in case of oil found in this Area , CFM recommendation is check of the MCD sump are correclt installed and check the O-ring condition and to perform oil system insepction if leakage is suspected per TASK 79-00-00-200-802-F00 2. External Oil System Inspection.